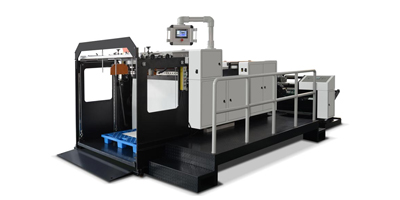

The following are the main advantages of the Roll-to-Sheet Cutting Machine, which is suitable for packaging, printing, electronics, automobiles and other industries:

Continuous automated cutting: directly cut roll materials into sheets of preset sizes at high speed, without manual unloading or frequent material changes, reducing downtime.

High speed and high capacity: It can process dozens of meters of rolls per minute, which is suitable for large-scale production, especially in scenarios with strong demand such as e-commerce packaging and printed materials.

Utilizes advanced CNC or digital controls to ensure exact cuts, producing uniformly sized sheets critical for industries like packaging and printing.

Optimize layout algorithm: support nested cutting of coils, intelligently plan layout according to sheet size, and reduce waste rate.

Adapt to different coil widths: adjustable cutting path, compatible with a variety of coil widths, and flexibly respond to order changes.

Support multi-specification cutting: one-click switching of different sheet sizes without changing molds, suitable for small batch and multi-variety customized production.

Diversified cutting modes: can realize single sheet, multiple sheet stacking, striping and then slicing functions to meet complex needs.

Minimizes manual intervention, lowering labor requirements and associated costs. Automated feeding and stacking further streamline operations.

Reduces worker exposure to cutting hazards, enhancing workplace safety by automating high-risk tasks.

Summary

The roll-to-sheet cutting machine significantly improves production efficiency and product quality through automation, high precision, and low loss, and is especially suitable for companies pursuing cost-effectiveness and flexibility.

GET A QUOTE