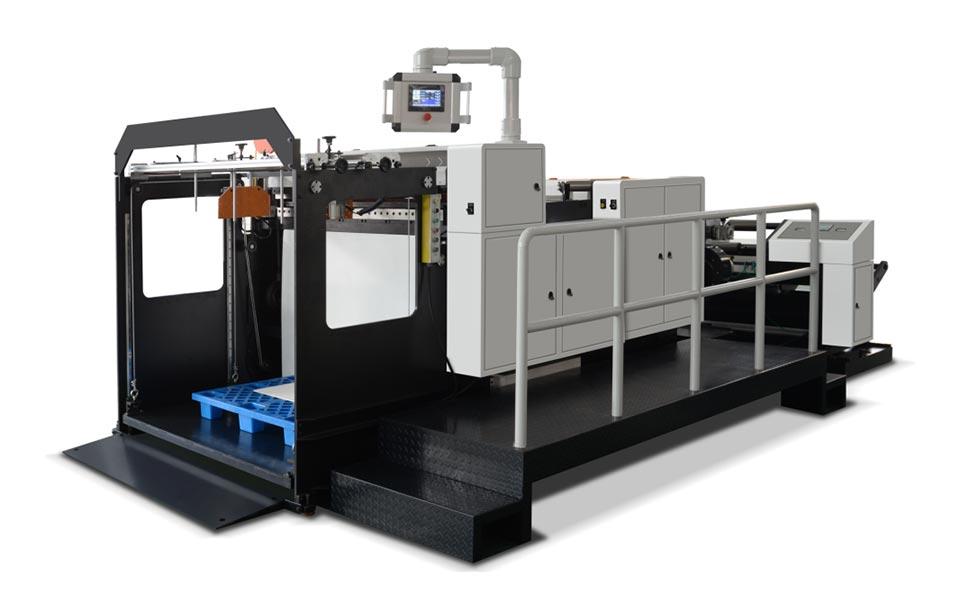

In numerous industrial production scenarios, the roll to sheet cutting machine plays a crucial role. Correctly choosing a suitable roll to sheet cutting machine is of great significance for improving production efficiency, ensuring product quality, and reducing costs. The following are the key points for selecting a suitable roll to sheet cutting machine.

I. Cutting Precision Requirements

1.Consideration of Precision Indicators

Firstly, note machine's cutting precision. ±0.1mm+ for high-precision needs (e.g. thin electronic comp. mats), ±0.5mm for lower needs (e.g. ord. pack. mats) to avoid high-cost over-precision.

2.Testing of Actual Samples

Request samples from the manufacturer or conduct on-site tests to visually evaluate whether the cutting edges are smooth and the dimensions are accurate. For industries with high precision requirements, such as optical film cutting, the actual precision performance of the samples is a key decision-making factor.

II. Adaptability to the Characteristics of the Cutting Material

1.Adaptability to Material Types

Clearly define the type of material to be cut, whether it is plastic film, paper, metal foil, or other special materials. Different materials have significant differences in hardness, toughness, and other characteristics. For example, cutting metal foil may require a machine with higher power and sharper cutting tools, while paper cutting focuses more on the matching of the sharpness of the cutting tools and the cutting speed.

2.Material Thickness Range

Determine the thickness range of the commonly processed materials and select a cutting machine that can cover this range. For example, in the production of handling 0.1 - 1mm thick films, a device with stable cutting performance within this thickness range should be selected to prevent the cutting effect from being affected or the machine from being damaged by materials that are too thin or too thick.

III. Cutting Speed and Efficiency

1.Matching with Production Scale

Select device's cutting speed based on enterprise scale order vol. Large enterprises need high-speed cutters like big pack. factories. Small or custom prod. suits moderate-speed, flexible machines to prevent idleness.

2.Functions for Improving Efficiency

Pay attention to whether the equipment has functions such as automatic feeding and receiving, which can reduce manual intervention, improve the overall production efficiency, and reduce labor intensity. For example, a highly automated roll to sheet cutting machine can achieve continuous uninterrupted cutting operations.

IV. Equipment Stability and Reliability

1.Brand and Reputation

Give priority to choosing well-known brands and roll to sheet cutting machines with a good market reputation. Brand manufacturers usually have more guarantees in terms of technological research and development, quality control, and after-sales service, and their products have been tested in the market for a long time and have high reliability.

2.Quality Inspection and Certification

Check whether the equipment has passed relevant quality inspections and certifications, such as ISO standard certifications. These certifications are a recognition of the equipment's quality and safety and can provide a certain reference for enterprise selection.

V. Convenience of Operation and Maintenance

1.User-Friendly Operation Interface

The operation interface should be simple and easy to understand, so that operators can quickly get started. Having an intuitive human-computer interaction interface, such as touch screen operation and graphical parameter settings, can reduce the probability of operational errors and improve production efficiency.

2.Convenience of Maintenance and Repair

The key components of the equipment should be easy to disassemble, install, and clean. For example, a machine with convenient tool replacement and easy cleaning can reduce maintenance time and costs. At the same time, good maintenance convenience helps to extend the service life of the equipment.

VI. Price and Cost-Effectiveness

1.Budget Consideration

Formulate a reasonable equipment procurement budget and screen roll to sheet cutting machines whose performance meets the requirements within the budget range. However, price should not be the only determining factor, and the cost-effectiveness of the equipment needs to be comprehensively considered.

2.Long-Term Cost Analysis

Evaluate the long-term operating costs of the equipment, such as energy consumption, tool wear, and maintenance costs. Although some equipment has a higher purchase price, if it has low energy consumption, simple maintenance, and a long service life, it may be more cost-effective in the long run.

GET A QUOTE